In an era defined by digital transformation, the metals industry is undergoing one of its most significant shifts in decades. From automation in fabrication to digital ordering platforms, suppliers and manufacturers alike are adapting to meet the needs of a fast-paced, precision-driven market. The once-traditional sector of metal supply is being reshaped by efficiency, accessibility, and sustainability — three factors driving the future of how raw materials are sourced and delivered.

A Shift in How Metals Reach the Market

Historically, metal procurement required extensive face-to-face dealings, local suppliers, and a reliance on longstanding trade networks. While personal relationships remain valuable, the introduction of digital tools has streamlined operations. Engineers and designers can now compare alloys, thicknesses, and finishes in moments, drastically reducing lead times and minimising waste. The convenience of rapid quoting systems and real-time stock updates allows companies to maintain project momentum without the delays once common in procurement cycles.

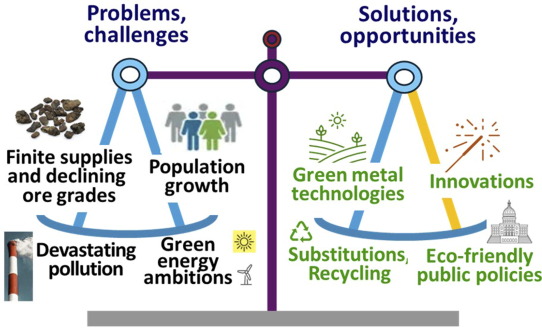

The Role of Sustainability and Efficiency

Sustainability has also emerged as a key pillar of the modern metals industry. Businesses are more conscious than ever of their environmental impact — not only in the production of metals but in their distribution and end use. The adoption of recycled materials, energy-efficient smelting methods, and low-carbon logistics solutions all reflect this growing responsibility. Moreover, transparency in the supply chain is becoming a competitive advantage. Clients increasingly want assurance that their materials are ethically and sustainably sourced.

Integrating Digital Commerce

Today’s businesses demand flexibility and speed. The rise of e-commerce within industrial sectors has made metals more accessible than ever. Platforms offering online metal sales have bridged the gap between large-scale suppliers and small workshops, enabling precise orders in low or bulk quantities without the traditional logistical hurdles. This digital accessibility empowers smaller manufacturers, start-ups, and hobbyists to compete with established players, fuelling innovation and diversification in design and production.

Smart Technologies and Automation

Beyond sales and sourcing, technological advancements have revolutionised how metals are processed. Robotics and AI-driven cutting systems now ensure a level of precision that manual processes cannot match. Automated bending, laser cutting, and CNC milling have reduced material wastage, improved repeatability, and lowered costs. Combined with digital tracking and monitoring systems, manufacturers can now anticipate wear, predict maintenance schedules, and optimise throughput in ways previously unimaginable.

Meeting Customer Demands in a Changing Market

Customers no longer seek just products — they seek partnerships. Modern suppliers must offer more than raw materials; they need to provide data insights, technical guidance, and end-to-end solutions. The companies that thrive are those that combine digital integration with traditional expertise. As competition grows, customer service and response times become key differentiators. Whether supporting construction, automotive, or aerospace projects, adaptability remains the defining trait of successful metal suppliers.

Global Trade and Market Volatility

The global metals market remains closely tied to economic trends, geopolitical factors, and resource availability. Price fluctuations in steel, aluminium, and copper are often influenced by trade tariffs, energy costs, and global demand. The recent emphasis on domestic production and secure supply chains has encouraged many countries to rethink their reliance on imports. While this shift can increase local opportunities, it also challenges suppliers to balance cost competitiveness with reliability.

The Future of Metal Supply

As the digital and physical worlds continue to merge, the future of metal distribution will likely blend e-commerce platforms, data analytics, and AI-driven logistics. Predictive demand forecasting could help prevent overproduction, while blockchain-based systems might ensure full transparency from mine to manufacturer. The evolution is already visible in how customers interact with suppliers — through live chat tools, digital quote systems, and automated delivery scheduling.

Ultimately, the transformation of the metal industry represents more than technological change — it’s a cultural shift. The future belongs to those who embrace innovation without abandoning the reliability and craftsmanship that define the sector’s legacy.